How do outdoor particulate matter concentrations measured using Ultrasonic Personal Air Samplers...

Revised PM2.5 1 LPM cyclone design

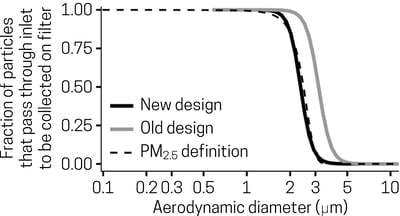

Access Sensor Technologies has improved the design of our PM2.5 1 LPM cyclone inlet to achieve a penetration efficiency that aligns more closely with the United States Environmental Protection Agency (US EPA) definition of PM2.5 (Figure 1), because recent tests indicated that the old (R0) design had a cutpoint (d50) that was closer to 3.0 µm than to 2.5 µm.

Figure 1. Penetration efficiency vs. aerodynamic diameter for the new (R1) and old (R0) PM2.5 1 LPM cyclone inlet designs compared to the US EPA definition of PM2.5.

You might have questions about this design change, including:

- "What does the difference between the old and new inlet designs mean for samples that have been collected using the old design?"

- "How will the change from the old to new design affect my measurements moving forward?"

In most situations, we expect the difference in mass sampled using the old versus new PM2.5 1 LPM inlet to be small; see Figure 2 for more information. Additionally, consider the following real-world examples:

- The difference in mass sampled using the old vs. new inlet would be 4% for the seasonally-averaged ambient aerosol mass distributions measured during both summer and fall in Pittsburgh, USA by Cabada et al. (2004; DOI: 10.1016/j.atmosenv.2004.03.004; Figure 3). This difference would range from 3% to 9% for the ambient aerosol mass distributions measured in Newark, NJ, USA by Zhao and Gao (2008; DOI: 10.1016/j.atmosenv.2008.01.032).

- Household air pollution from solid fuel combustion has been reported to have a unimodal distribution with a mass median diameter ≈ 0.3 µm and a geometric standard deviation ≈ 1.7—1.8 (Just et al., DOI: 10.1021/es304351p). For such a distribution, the difference in mass sampled using the old vs. new inlet would be less than 1%.

- Figure 5 in Arku et al. (2018) DOI: 10.1016/j.envint.2018.02.033

- Figure 2 in Pillarisetti et al. (2019) DOI: 10.1016/j.envint.2018.11.014

- Figure 2 in Burrowes et al. (2020) DOI: 10.1111/ina.12638

Additional questions you might have

Which PM2.5 1 LPM inlets will be available for purchase moving forward?

Moving forward, only the new PM2.5 1 LPM inlet design will be available for purchase.

How will I know which PM2.5 1 LPM inlet design I am using?

Compare the bottom side of the inlet, paying special attention to any text engraved there, to Figure 4 and Table 1.

|

||

| (a) Old (R0) design | (b) Old (R0) design | (c) New (R1) design |

| Figure 4. Compare plastic insert on the bottom side of your PM2.5 1 LPM inlet to these images to determine whether the inlet uses the old (R0) or new (R1) PM2.5 1 LPM cyclone design. | ||

| Image in Figure 4 | Insert plastic color | Engraved text | PM2.5 cyclone design | Penetration efficiency in Figure 1 |

| (a) | Black (opaque) | None | Old (R0) | Solid gray line |

| (b) | Brown (translucent) | "GEN2P3" | Old (R0) | Solid gray line |

| (c) | Brown (translucent) | "GEN2P3R1" | New (R1) | Solid black line |

NOTE: For GEN2P3 inlets, the engraving on the top side of the black aluminum cap might differ from the engraving on the bottom side of the brown plastic insert. For example, the cap might be engraved with “GEN2P3R0” and the insert might be engraved with “GEN2P3R1”. Such a discrepancy does not indicate a problem. The design change discussed in this technical bulletin affects the plastic insert; therefore, the engraved text on the bottom of the plastic insert is what indicates whether the inlet uses the old or new PM2.5 1 LPM cyclone design. GEN2P3R1 inserts, which feature the new design, are compatible with all GEN2P3 caps.

What if I am using the PM2.5 2 LPM inlet?

Our PM2.5 2 LPM inlet is not affected by this change. Data collected by Access Sensor Technologies in April 2024 indicates that our PM2.5 2 LPM inlet performs in accordance with the US EPA definition of PM2.5. See our Size-Selective Inlet Product Information Sheet or Size-Selective Inlet User Guide for performance data.

Resources

Download a two-page PDF document with a summary of this information here.

Learn more about our size-selective inlets for particulate matter sampling on our Accessories page.